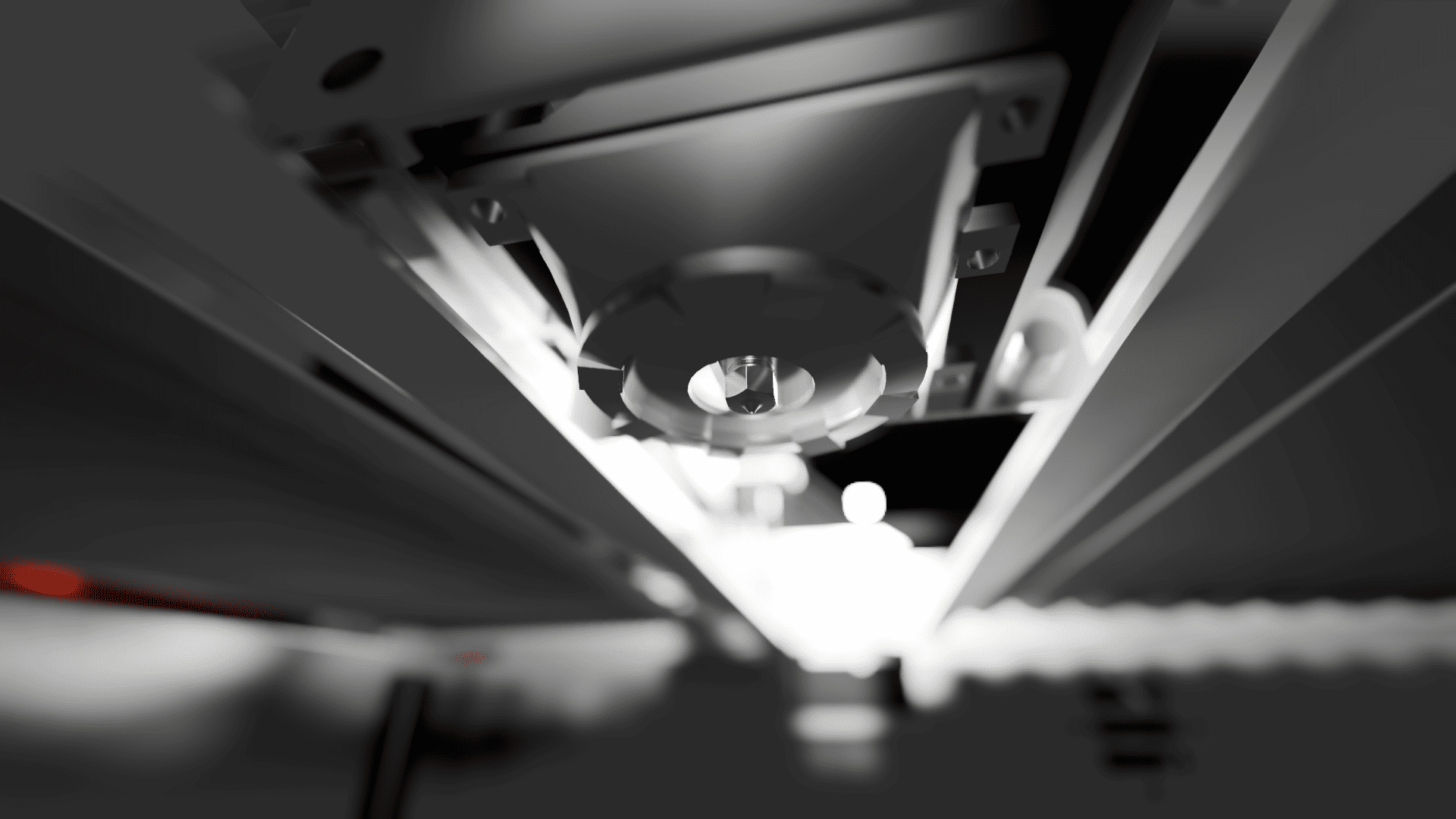

The Factory in a Single Box.

We are replacing fragmented production lines with intelligent, modular manufacturing cells.

Consolidated Production

Traditional manufacturing requires disjointed chains of specialized machines, vendors, and logistics. We consolidate these steps into a single, software-defined system that utilizes modular toolheads to process parts efficiently.

Extreme Agility

Shorten development cycles by streamlining production workflows. Iterate on hardware as fast as software.

Digital Thread

Full process control and data logging for every part, ensuring compliance with aerospace and medical standards.