Unleash Your Potential With DUO

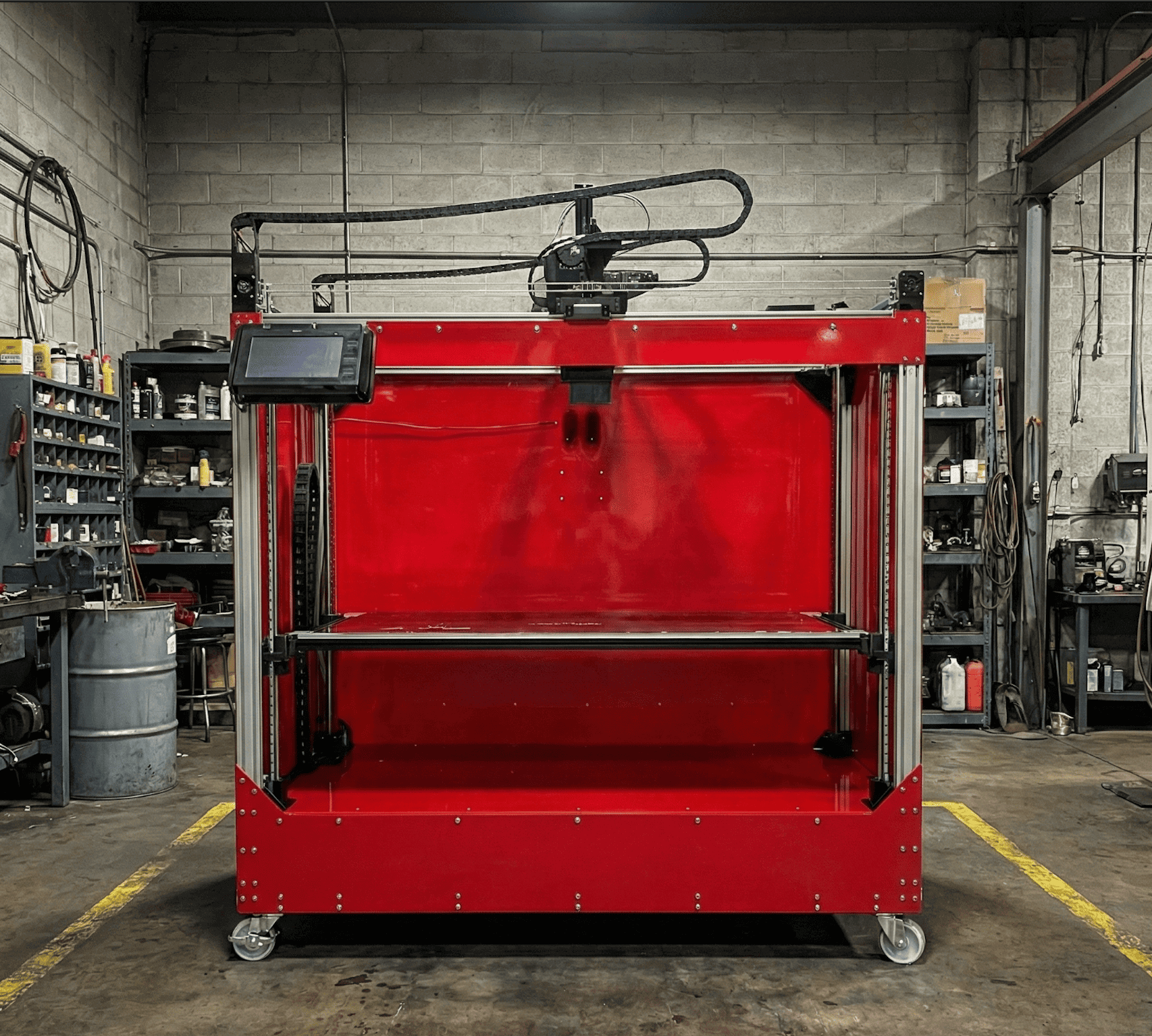

When Creative 3D Technologies introduced DUO, it disrupted the 3D printing industry. A single machine with truly independent dual print heads capable of handling both small precision parts and large format prints. This disruptive technology proved multi-material capability was not just possible, but essential, and became the foundation that evolved into the revolutionary EVO platform.

- Increased productivity with independent dual print heads

- Ease of use with drag-and-drop material handling

- Expandable printing capability for both small and large format FDM

.png)