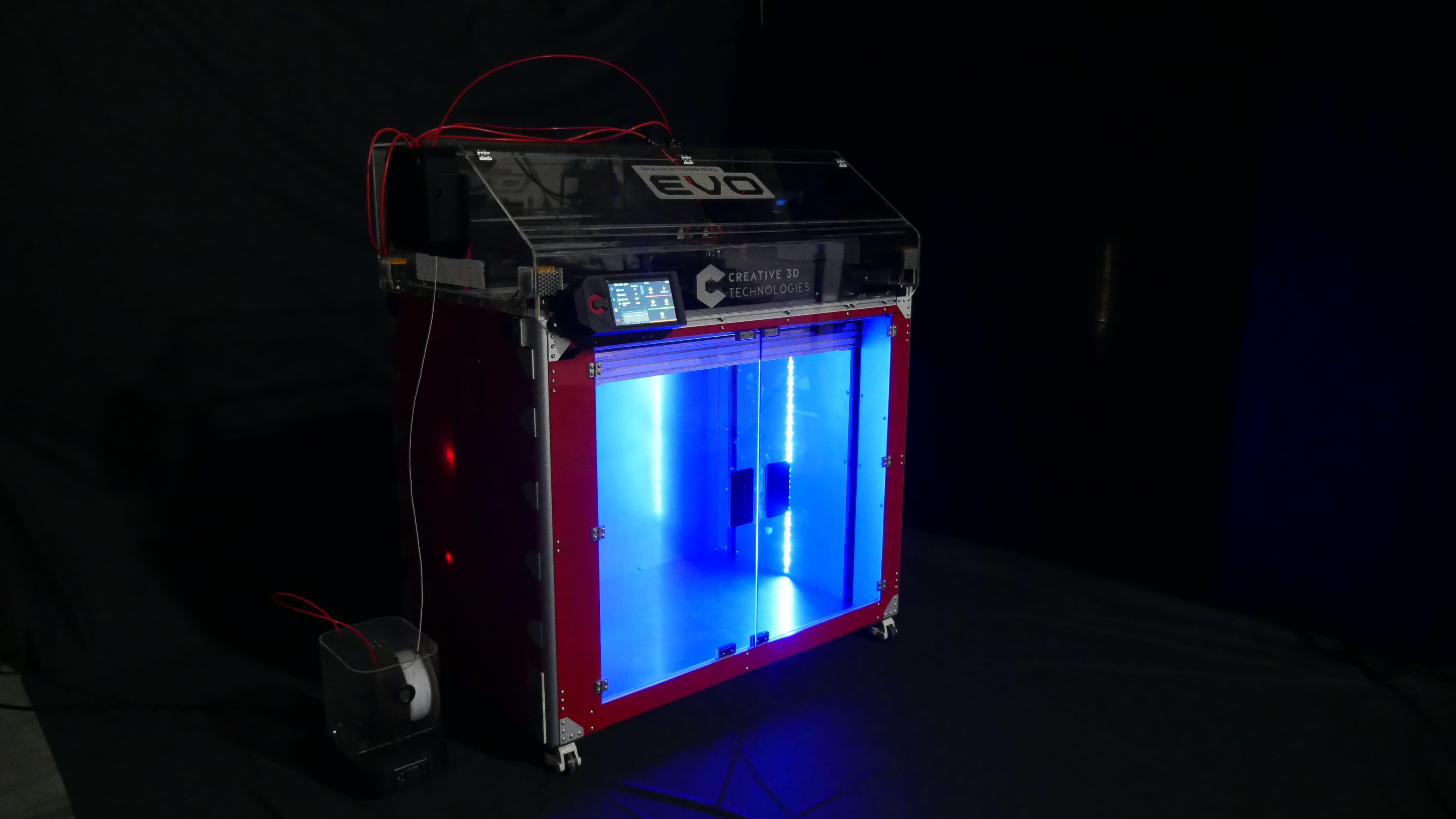

This is EVO.

The gap between prototyping and production is finally closed. EVO combines the agility of a lab machine with the rigidity of a factory workhorse.

Built for Acceleration

A rigid metal chassis designed to handle 2000mm/s² acceleration without vibration. Speed is nothing without stability.

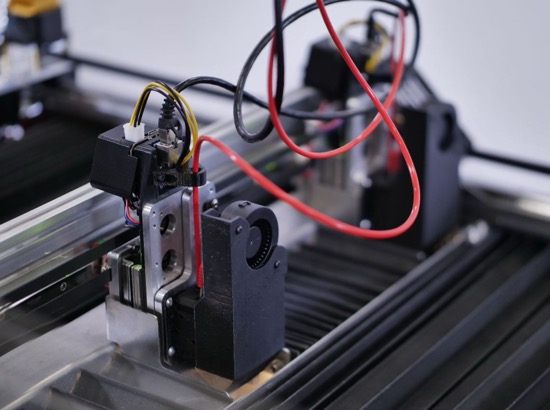

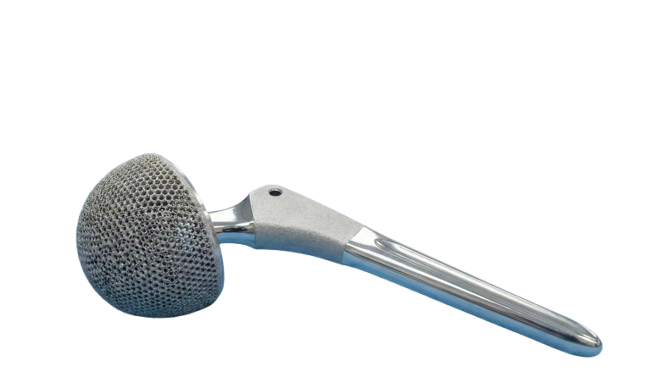

Evolving Intelligence

Modular toolheads identify themselves instantly. Switch from high-flow PLA to carbon-fiber nylon in seconds, not hours.

Production Scale

With a massive build volume, EVO doesn't just print parts, it prints entire batches in a single run.